THE FUTURE OF DESIGN AND MAKING

The Design and Manufacturing Futures Laboratory is researching and creating the tools and technologies of tomorrow, providing game-changing capability for the design, manufacture, operation and disposal of next generation products and machines.

Projects

AllDesignMakeManage

🔍

Researchers in Residence The UKRI Innovation Launchpad: Researcher-in-Residence promotes academic engagement and is designed to enable researchers to work with the Catapults...

21st Century Prototyping Technologies Design today is both physical and digital. That’s especially true when designing new products. Designers need to bring...

Quantum Computer Aided Engineering Classical computation, while powerful, faces limitations in tackling the breadth and complexity of design problems. These limitations are...

Physical-Digital Prototyping This project took place as a summer internship in July and August 2021. The project was looking at how we can...

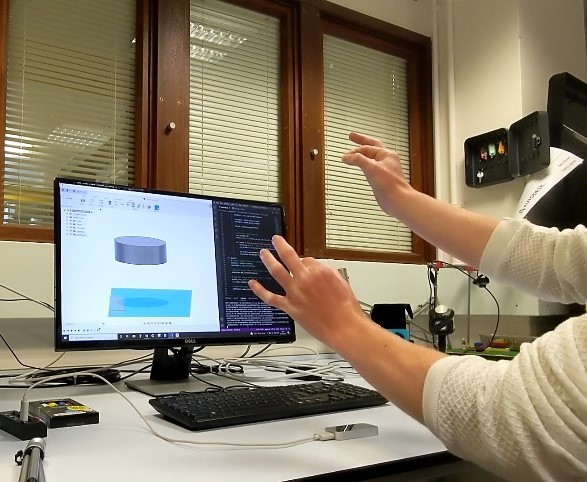

Gesture-controlled CAD This project took place as part of a summer internship in 2021. The initial goal of the project was to...

Haptics in Engineering Design Haptics is the study of touch, and its application in engineering has risen in recent years due to...

Emulating Mass Properties With 3D Printing When 3D printing products it is common for the fabricated component to have significantly different mass...

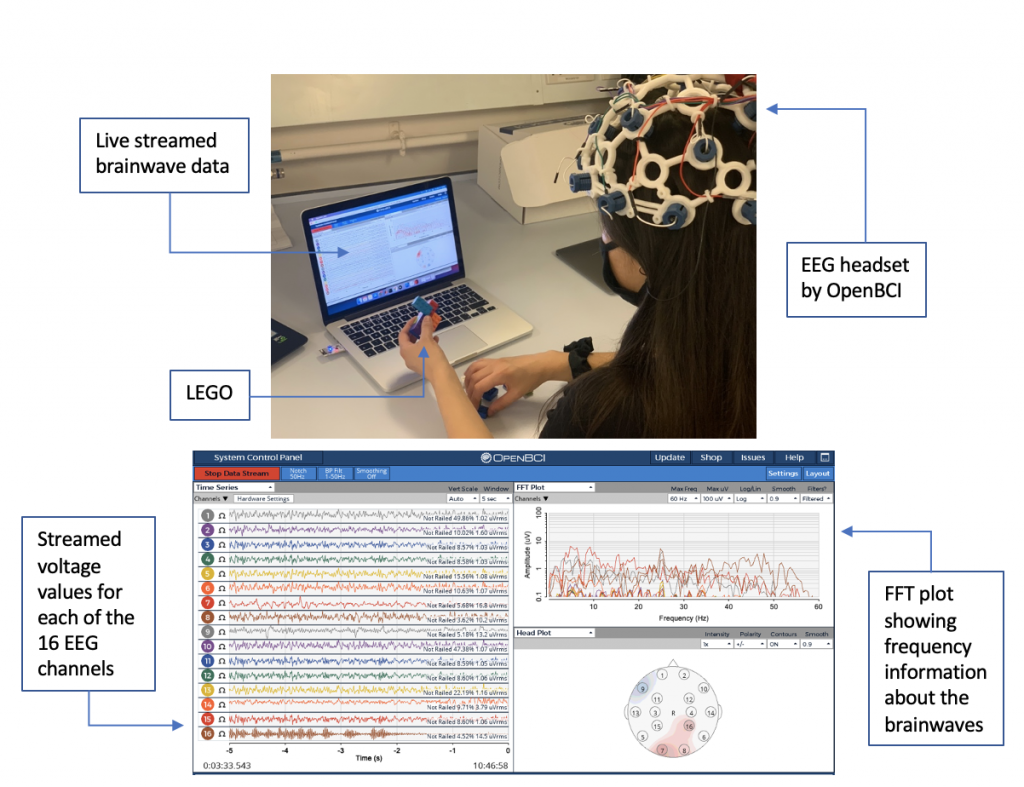

The Neuro-cognition of Digital and Physical desiging When prototyping, a number of different tools and technologies exist in physical and digital domains. ...

Language of Collaborative Manufacturing The Language of Collaborative Manufacturing was a £1.9M research project sponsored by the Engineering and Physical Sciences Research...

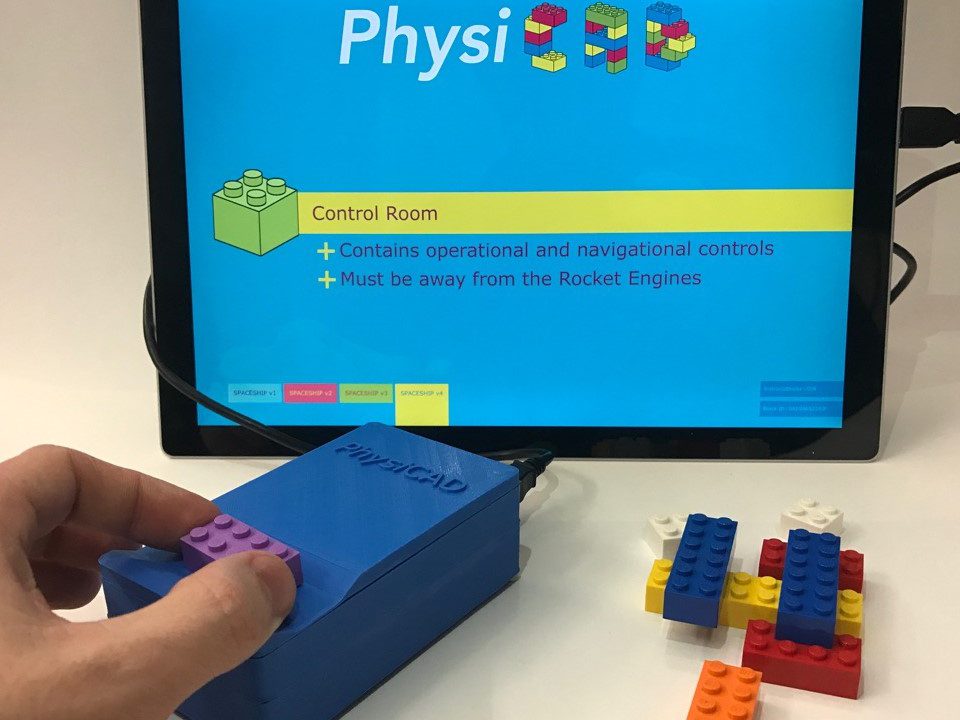

PhysiCAD While CAD systems have been immensely beneficial they require specialist knowledge and expertise for their operation, particularly where advanced modelling, simulation...

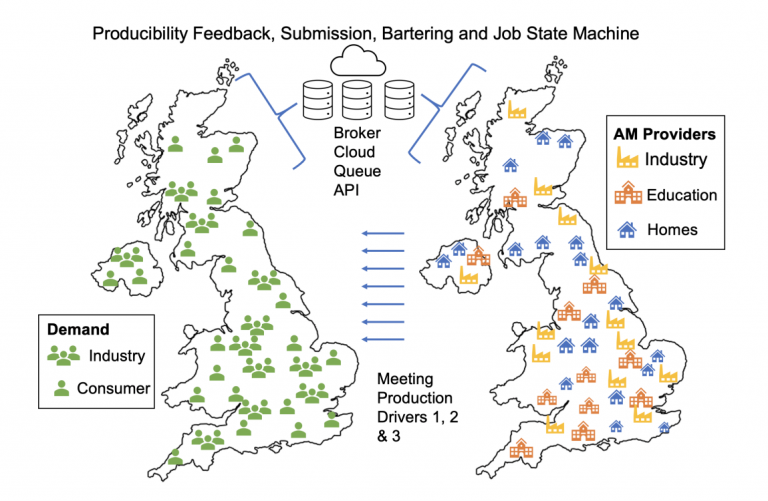

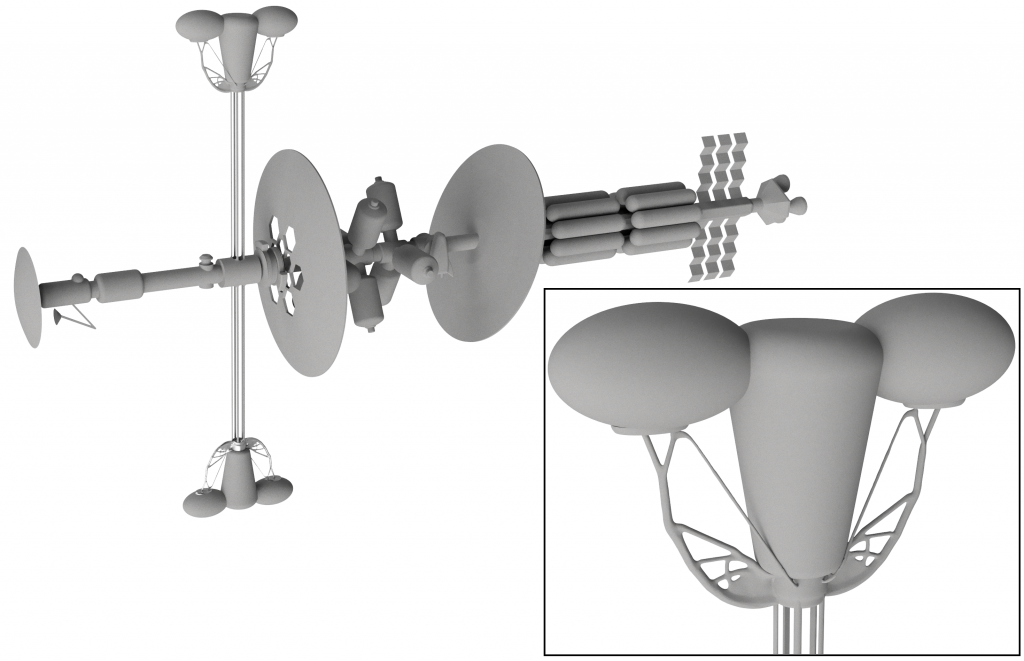

Brokering Additive Manufacturing (BAM) https://dmf-lab.co.uk/wp-content/uploads/2021/10/agents.mp4https://youtu.be/-Ioozler69Ahttps://youtu.be/NIVwWAGOLS8 Society is driving the need for Responsive...

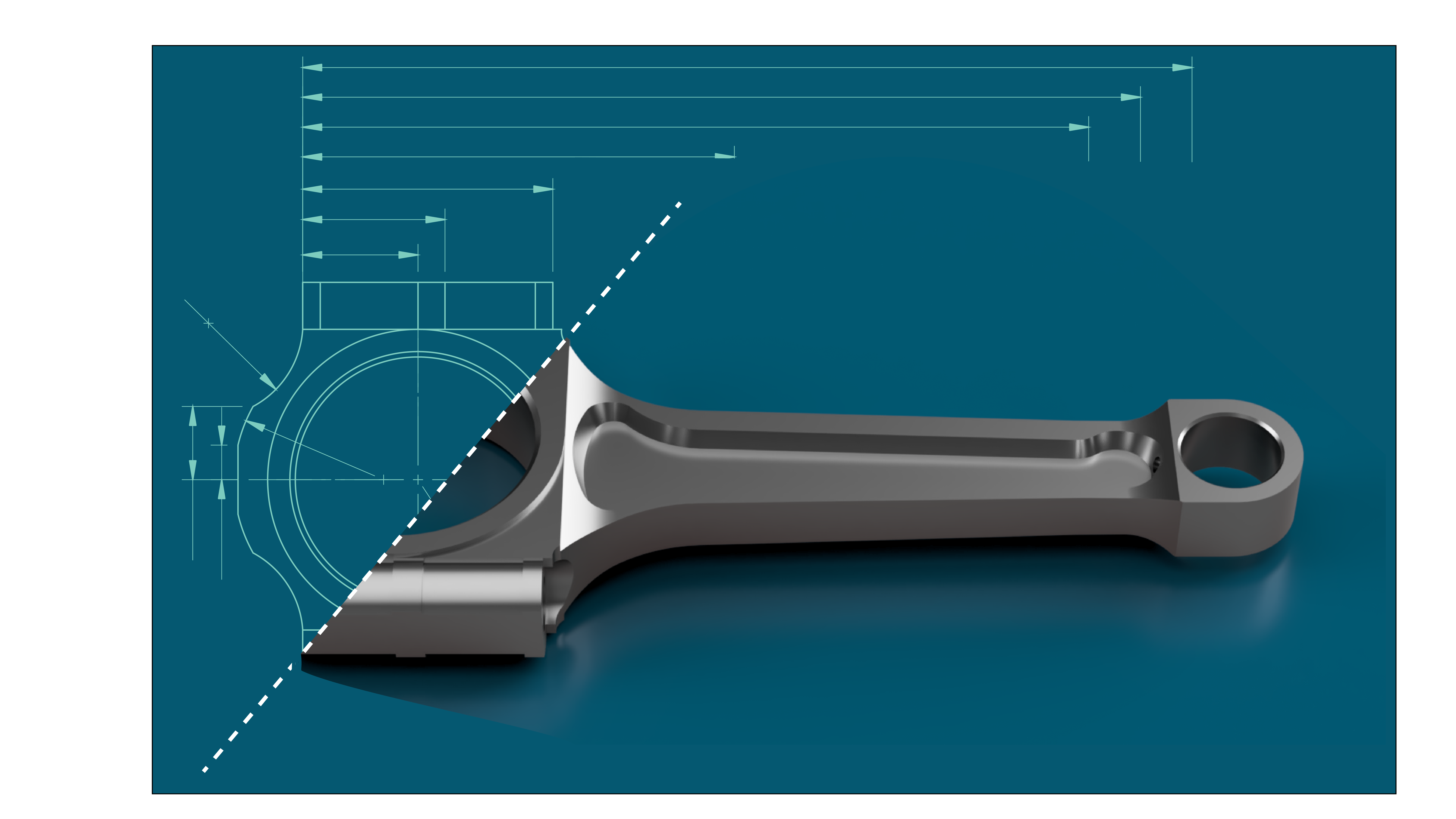

Design by Computers Over the last two years the DMF lab have been partnering with Autodesk to apply their cutting-edge design tools...

Project Clean Access PCA Toolkit Initiatives DMF Lab Experience Our skills like in rapid manufacture and effective/efficient low-end production using rapid manufacture...

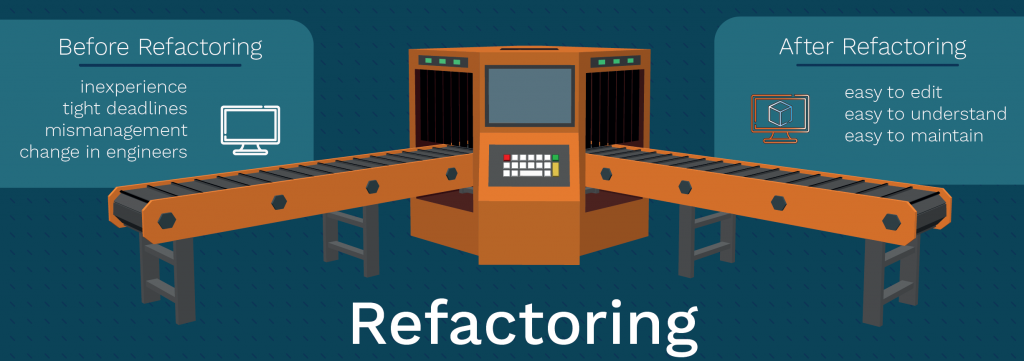

We are running an Editability Study of CAD models. This study aims to inform further work on CAD models Design Intent and...

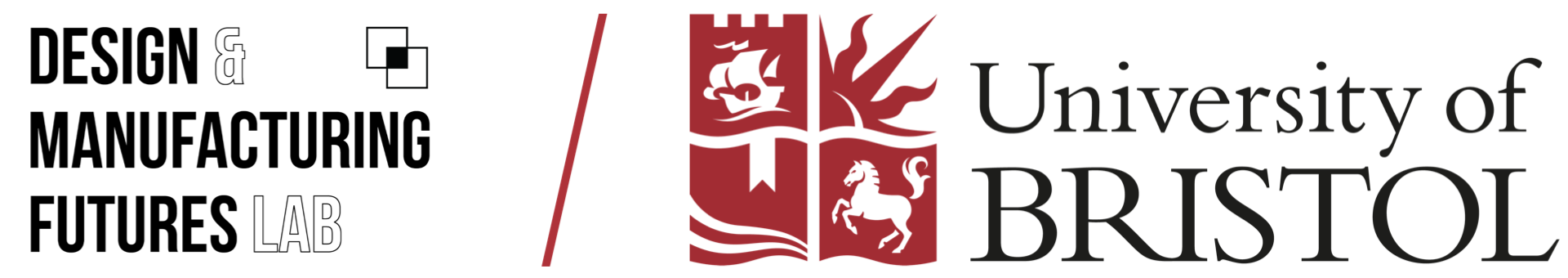

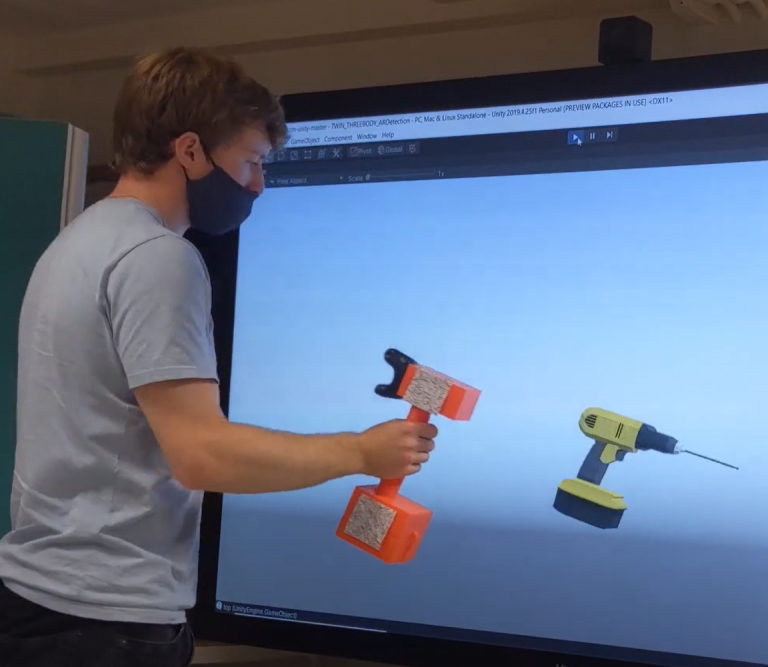

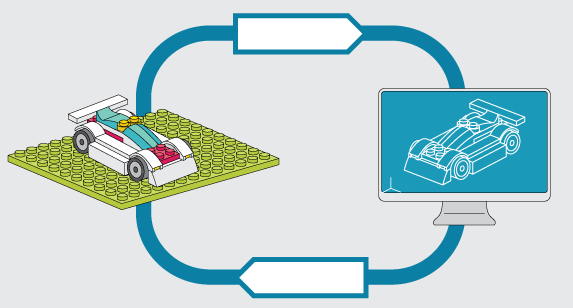

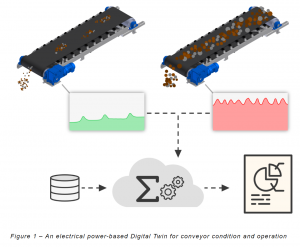

Prototwinning In all engineering disciplines a combination of digital and physical models is necessary to support the progression of the design process...

Project Lead: Peter Rosso CAD models often need to be modified and/or reused. Thus, it is essential to create easily editable CAD...

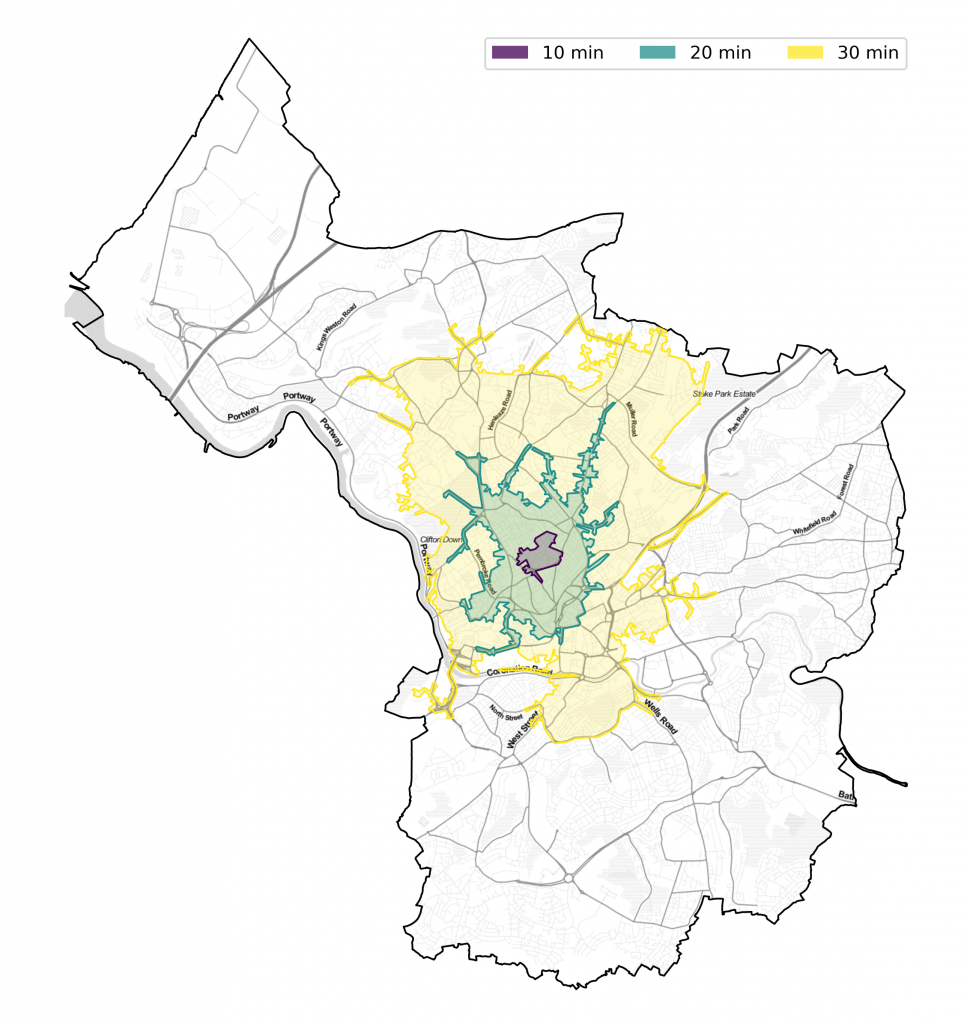

Background Transport poverty has long been cited as one of the key limitations for individuals and their communities to achieve their potential...

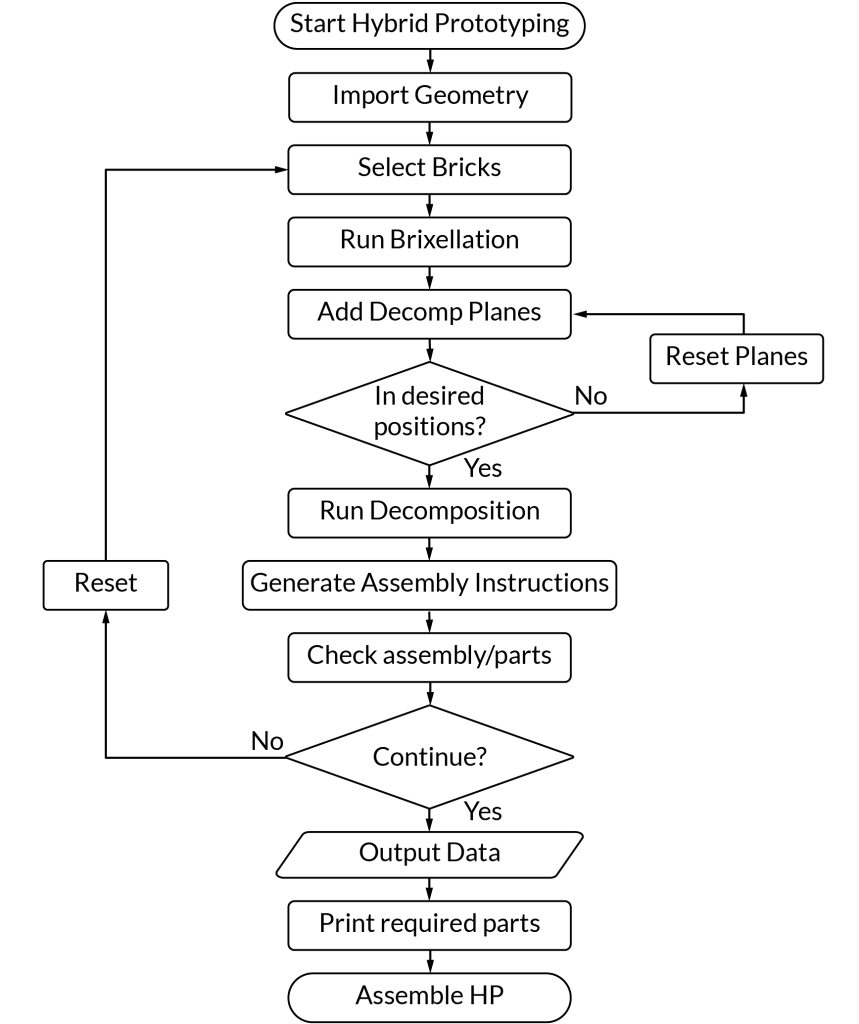

As the PhD draws to a close, I have produced a demonstration video of the Brixelation tool. It allows Hybrid Prototypes (LEGO...

by David Jones and Owen Freeman Gebler As part of the ProtoTwinning project (https://gow.epsrc.ukri.org/NGBOViewGrant.aspx?GrantRef=EP/R032696/1), we are evaluating metrology methods for digitally...

See the latest article from the Lab on The Future Factory forum https://www.thefuturefactory.com/blog/24. In the article Ben looks at the history of the...

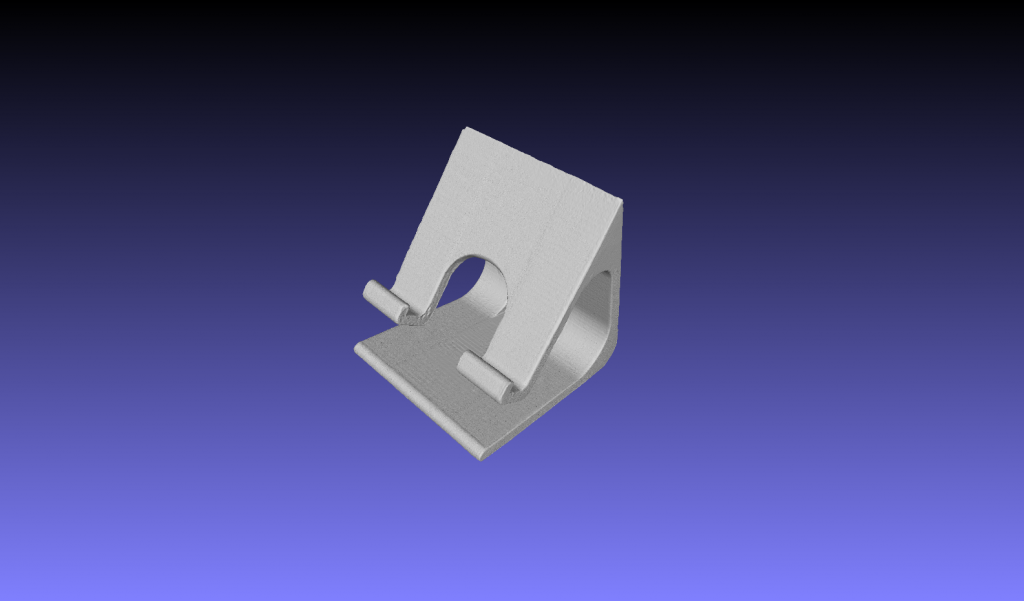

I’ve started work on my first sprint looking at coupling additive and subtractive manufacturing (termed hybrid manufacturing) for use within digital twinning...

On Jan 9th I gave a seminar to Babcock International Group’s Innovation Forum on Digital Twins. In the talk I covered a...

The potential benefits of coupling LEGO and FDM printing in a hybrid prototyping have been shown through idealised simulations, however it needs...

How do you design a city? What should it look like? What would living there be like? The Design and Manufacturing Futures...

Brixelate and Kitify are two Blender addons written in Python that help designers create physical, editable versions of their designs. Check out...

Anarchic Manufacturing Exploring distributed manufacturing systems, where decision making autonomy and authority is delegated at the lowest level in a manufacturing system...

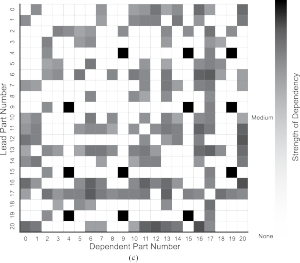

Mapping the Hidden Dependencies of Engineering Systems Modern engineering systems are even more complex than they appear on paper. Components and systems...

InstructiBlocks Problem Managing complexity of design constraints and avoiding violations is challenging. We need to be able to explore design opportunities in...

Seamless Digital-Physical Prototyping The product development process requires an orchestration of physical and digital models of different qualities, fidelities, and capabilities. A...

Usage Profiling of Rotating Machines Recent Posts...

Mixed Media Building Asset Management A short Innovate UK project working with Altuity Solutions Ltd to develop novel user interfaces for building...

Project Lead: Peter Rosso Engineering environment uses editable and convenient geometric models for solid representation. However, industries with long-life products still store...

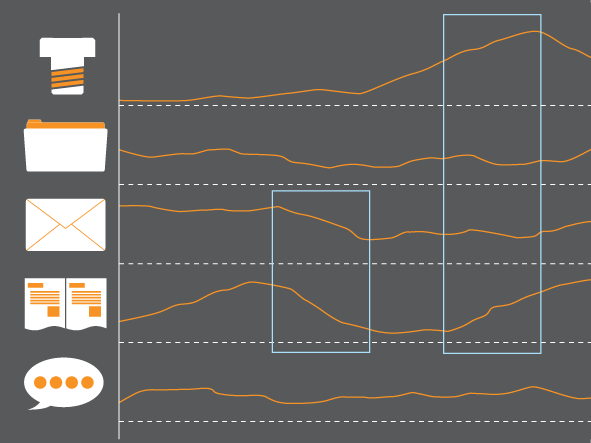

Model Based Information Navigation Our industrial partners on the project, The Airbus Group’s Knowledge Management team, tasked us with improving access to...

Democratisation of Design Project Lead: Mark Goudswaard Current means of manufacturing are bad for people and planet. Additive manufacturing technologies can enable low...

Using physical objects when prototyping has enormous benefits and affords tangibility and presence that are lacking from digital files. However creating prototypes...

3D printing has the potential to revolutionise the way we consume goods. The technology should be able to facilitate low-cost, personal manufacture...