Brokering Additive Manufacturing (BAM)

Society is driving the need for Responsive Manufacturing and requires fundamental research to come-up with strategies that can complement existing Modern Manufacturing Practice (MPP) (e.g. batch, mass and just-in-time).

Driver 1 is Big Demand, which concerns the response, volume, variety and location in demand, arising from large-scale events, such as COVID-19, Brexit, Disaster Response, Global Financial Crisis and War, and mass-customisation/bespoke products simply cannot be met by MPP, such as automotive production lines and supply chains, as they have been optimised for particular products.

Driver 2 is accommodating dynamic production constraints. COVID-19’s measures of social distancing and tiering system as well as trade disputes (Brexit and America vs. China) have shown how quickly MPP can be severed, significantly reducing supply to society.

Driver 3 is facilitating manufacturing independence. MMP has enabled large developed nations – America, China, EU, Japan, South Korea, India – to provide production capability that developed smaller (e.g. UK, Switzerland) and developing nations would not have had access to. However, many society’s view manufacturing independence as a strategic goal (e.g. Reshoring) especially in light of Drivers 1 & 2 where a nations reliance on other nations’ manufacturing capability leaves them vulnerable and without the capability to combat their national needs.

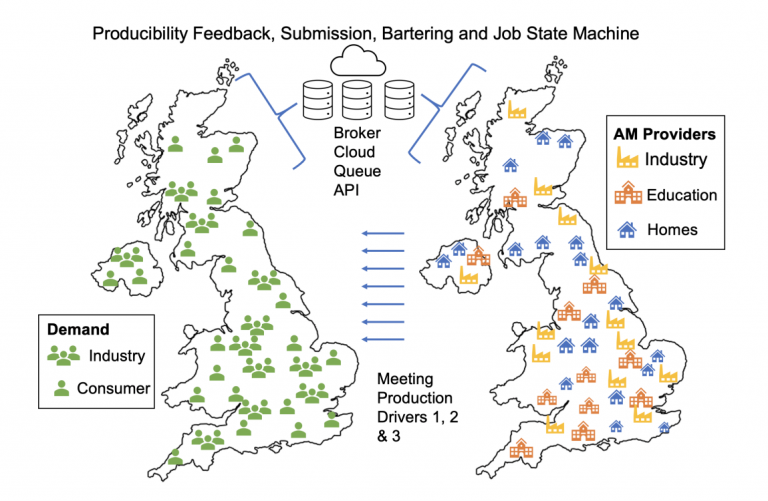

Brokered Additive Manufacturing (BAM) will prove that these drivers can be met through a nation’s highly distributed and diverse Additive Manufacturing (AM) capability if it can be effectively brokered.

BAM brings together world-leading researchers from the Schools of Civil, Mechanical and Aerospace engineering and Business Management, 300+ leaders in the AM industry (GTMA, AMUG, AT 3D Squared) and Model-Based Systems Engineering (CFMS), and industry/government initiatives (Reshoring UK) to create novel brokering of highly distributed and diverse manufacturing systems.

BAM’s transdisciplinary approach will see the team:

- profile Big Demand, dynamic production constraints and local, regional, national and global contexts to facilitate independence.

- develop Business Models and Government Policy.

- characterise AM capability.

- create Production System boundary condition models and agent-based models of BAM that simulate both human and machine brokering of jobs at community, regional, national and international scales.

BAM solutions will be evaluated through controlled lab experiments, living labs and development of industry demonstrators. The solutions will give rise to a new class of production system that broker highly distributed and diverse manufacturing capability (e.g. AM). This will underpin factories of the future that are not confined to single facilities but are as diverse and distributed as the manufacturing capability they house, revolutionising society’s production giving it greater flexibility and responsiveness to meet our future needs.

Meet the Team

Research Outputs

Papers

- Z. Neu, B. Hicks, and J. Gopsill. “Operating Minimally Intelligent Agent-Based Manufacturing Systems across the Average Demand Interval – Coefficient of Variation (ADI-CV) Demand State Space.” In: International Journal of Production and Manufacturing Research (2023). View.

- J. Gopsill, M. Goudswaard, L. Giunta, C. Snider, and B. Hicks. “Optimal configurations of minimally intelligent additive manufacturing machines for makerspace production environments”. In: International Journal of Artificial Intelligence in Engineering Design, Analysis and Manufacture (2023). View

- H. Felton, O. Schiffmann, M. Goudswaard, J. Gopsill, C. Snider, R. Real, A. McClenaghan, and B. Hicks. “Maker communities and the COVID-19 pandemic: a longitudinal analysis of Thingiverse’s response to supply shortages”. In: Royal Society Open Science 10.9 (2023), p. 230790. View

- O. Peckham, M. Goudswaard, C. Snider, and J. Gopsill. “What to Share? A Preliminary Investigation into the Impact of Information Sharing on Distributed De-centralised Agent-Based Additive Manufacturing Networks”. In: Advances in

Production Management Systems. Production Management Systems for Responsible Manufacturing, Service, and Logistics Futures. Ed. by E. Alfnes, A. Romsdal, J. O. Strandhagen, G. von Cieminski, and D. Romero. Cham: Springer Nature Switzerland, 2023, pp. 533–547. isbn: 978-3-031-43666-6. View - L. Giunta, B. Hicks, and J. Gopsill. “A Living Lab Platform for Testing Additive Manufacturing Agent-Based Manufacturing Strategies”. In: 33rd CIRP Design Conference. 2023. View

- M. Goudswaard, C. Snider, M. Obi, L. Giunta, K. Ramli, J. Johns, B. Hicks and J. Gopsill. “Required parameters for modelling heterogeneous geographically dispersed manufacturing systems”. Procedia CIRP. 2022. View

- L.Giunta, M. Obi, M. Goudswaard, B. Hicks and J. Gopsill. “Comparison of Three Agent-Based Architectures for Distributed Additive Manufacturing”. Procedia CIRP. 2022. View

- J. Gopsill, M. Obi, L. Giunta and M. Goudswaard. “Queueless: Agent-Based Manufacturing for Workshop Production”. Proceedings of the 16th International KES Conference on Agent & Multi-Agent Systems: Technologies & Applications. 2022. View Watch Presentation

- M. Obi, C. Snider, L. Giunta, M. Goudswaard and J. Gopsill. “Coping with diverse product demand through agent-led type transitions”. Proceedings of the 16th International KES Conference on Agent & Multi-Agent Systems: Technologies & Applications. 2022. View Watch Presentation

- M. Goudswaard, J. Gopsill, A. Ma, A. Nassehi, and B. Hicks. “Responding to rapidly changing product demand through a coordinated additive manufacturing production system: a COVID-19 case study”. In: Proceedings of the Manufacturing Engineering Society International Conference. 2021. View

- J. Gopsill, M. Goudswaard, C. Snider, J. Johns, and B. Hicks. “Achieving responsive and sustainable manufacturing through a brokered agent-based production paradigm”. In: Proceedings of Sustainable Design and Manufacturing. 2021. View Watch Presentation

Opensource Packages

- Living Lab Website. V2 Code | Website. V1 (Deprecated) Code | Website.

- Typescript client for Prusa-Link. NPM | GitHub | Docs.

- Typescript client for the on-machine Ultimaker API. NPM | GitHub | Docs.

- Typescript client for the OctoPrint API. NPM | GitHub | Docs.

- Typescript client for Markforged Eiger.io AM Fleet Manager. NPM | GitHub | Docs.

- Typescript client for Repetier Server. NPM | GitHub | Docs.

- Typescript client for the Ultimaker Cloud API. NPM | GitHub.

- Typescript client for the HP 3D Printing API. NPM | GitHub.

- Typescript client for Thingiverse. NPM | GitHub.

- Typescript client for MyMiniFactory. NPM | GitHub.

- BAM Broker. GitHub

- Web Serial Printing. Demonstrator Website | GitHub | Blog

- Typescript client for Grants on the Web. NPM | GitHub.

- Typescript client for Crossref. NPM | GitHub.

Recent Posts

Presenting at Transdisciplinary Engineering 2024 (TE2024)

James Gopsill presented his paper on Distributed Additive Manufacturing at TE2024.

Crossref Client referenced in Crossref Documentation

We opensourced our crossref API client written in Typescript and it has been referenced in the CrossRef documentation.

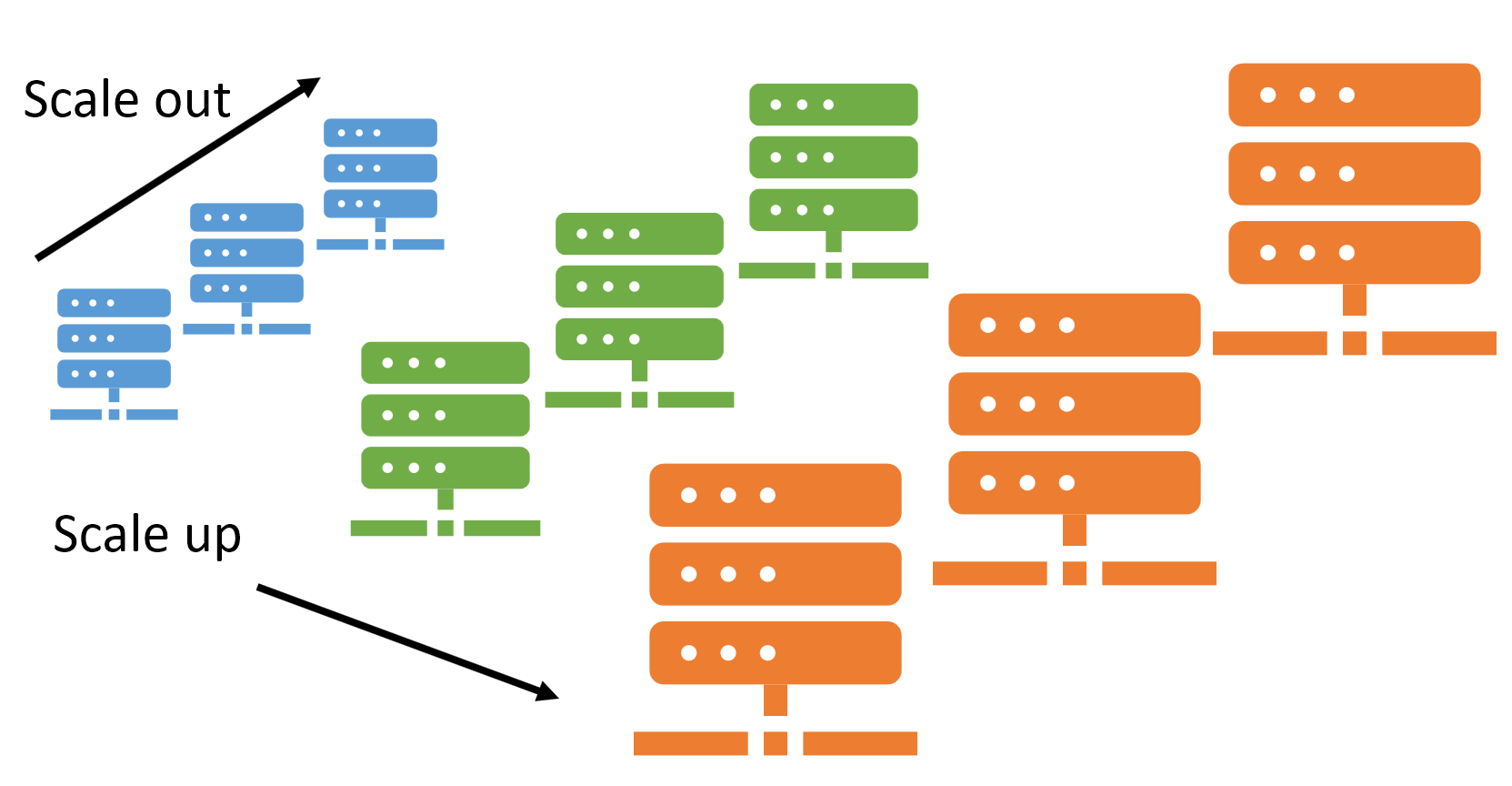

Scaling up BAM

In this post, we discuss the computational requirements in scaling up an agent-based manufacturing service.

DMF Lab @ FormNext 2022

The DMF lab have just returned from FormNext 2022. What an amazing showcase of AM capability. Read on to find out what we showed and learnt from the week.

BAM attend UK-AM Relaunch Event, October 2022

On 5th October 2022, BAM project team members, Jennifer Johns and Kautsar Ramli attended the AM-UK Relaunch event at the National Centre for Motorsport Engineering (NCME) in Bolton.

Meet BAM’s Summer Intern – Soo-Hwa Kim

Soo-Hwa Kim is investigating the affordances of including machines agents that have memory that enable them to make predictions on the incoming workflow as well as store multiple jobs at any one time.

Meet BAM’s Summer Intern – Owen Peckham

Owen Peckham is investigating the Minimum Viable Information requirements to broker deals between jobs and machines, as well as examining the affordances of including additional information during the brokering process.

DMF @ DCC’22

The DMF attended the tenth International Conference on Design Cognition and Computing (DCC’22) in Glasgow and received the best poster prize and runner up in the best paper award!