Emulating Mass Properties With 3D Printing

When 3D printing products it is common for the fabricated component to have significantly different mass properties to the as-designed product. This is especially true in early-stage design prototype fabrication, where understanding the geometric form of a prototype leads to rapid production of the artefact. There are several reasons for this, but the main three are:

- Neglecting to include internal components when generating a geometric representation of the external shell,

- Using a lower density thermoplastic rather than the designed-for material, and,

- Using a low-density infill pattern to save on material/production costs and time.

For some applications, this may not be important, however, it is common for stakeholders to interact with early-stage products to understand feel. Inevitably, the mass properties an artefact exhibits changes the perceived feel – with the force and torque required for interaction being directly linked to the product’s mass properties. As such, it is hypothesised that a method through which mass properties can be emulated in 3D printed products would be desirable.

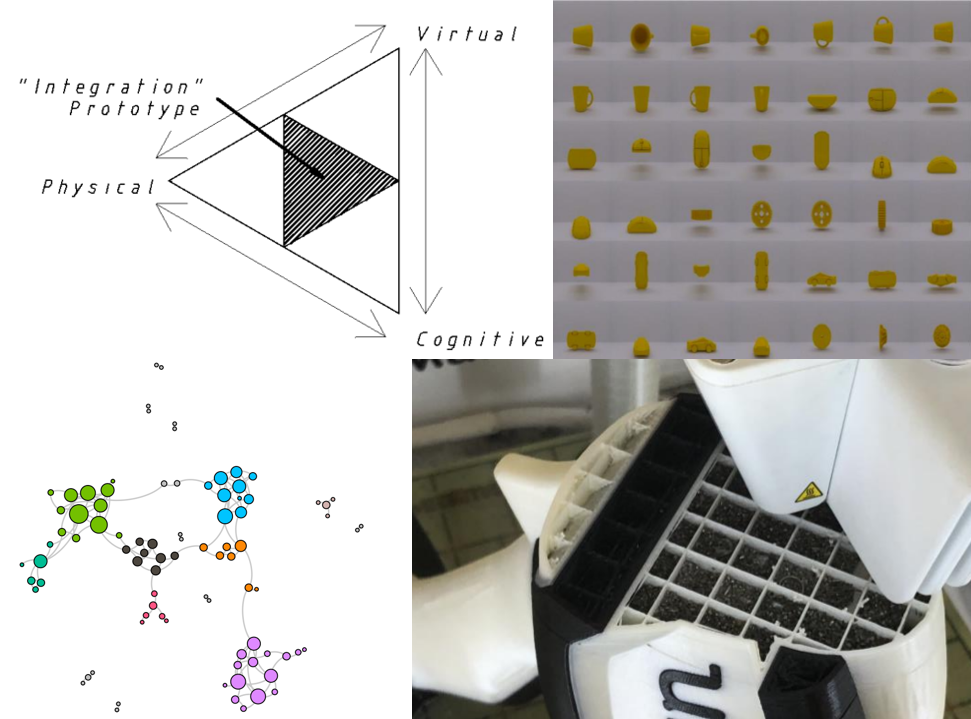

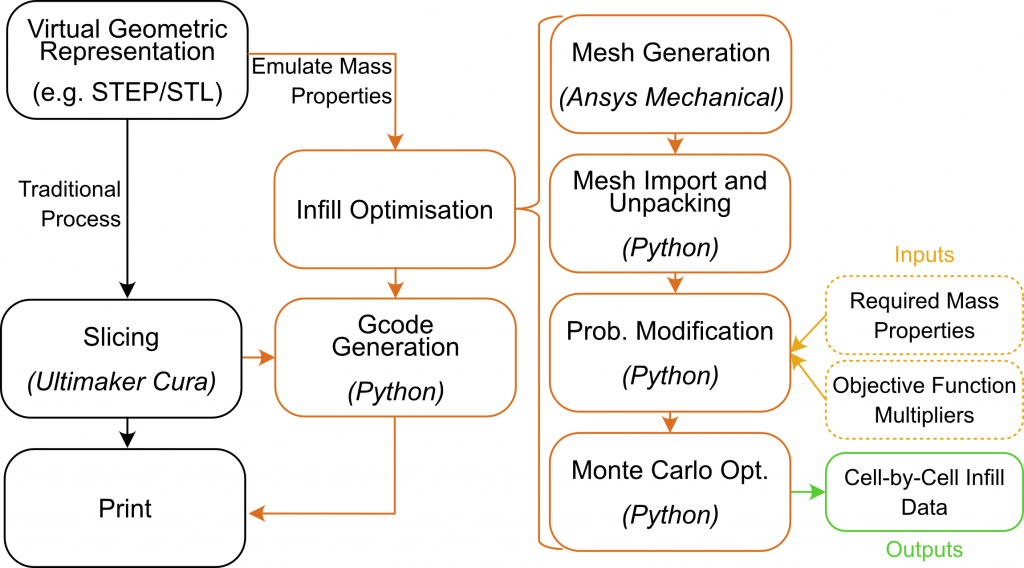

This work demonstrates a methodology (presented below) through which product mass properties can be emulated using a standard 3D printing process (FDM/MEX/FFF) and machine. Written in Python, the code is able to produce a cellwise breakdown highlighting where mass needs to be placed to best emulate the desired mass properties. Work is currently continuing to slice a set of example products ready for 3D printing.

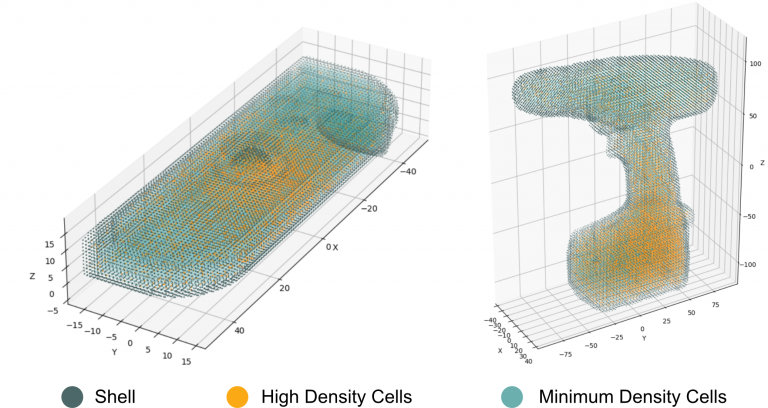

Initial results have been promising, with several case studies considered. The results from two of these – a Nintendo Switch JoyCon and Bosch electric hand drill – are shown below. The mass error was less than 1g for each of these parts, and the centre of mass position error less than 1 mm (averaged).

This work is currently being written up for a journal paper. Check back soon for updates on publication and further developments.

People

Blog Posts

DCC 2020 – Poster Presentation (Presented by 8-bit Harry!)

Harry today presented his poster titled “Investigating strategies for mass property replication in 3D printed prototypes” at DCC2020 – virtually, of course, given the world we now live in! The poster aims to introduce the use of variable infill for the purpose of replicating mass properties between as-designed and as-fabricated parts when using rapid prototyping. […]

Design 2020

We would like to thank the organisers of Design 2020 for a fantastic virtual conference, with four papers presented by member of the group: A FRAMING OF DESIGN AS PATHWAYS BETWEEN PHYSICAL, VIRTUAL AND COGNITIVE MODELS presented by David, DEMOCRATISING DESIGN THROUGH SURROGATE MODEL CONVOLUTIONAL NEURAL NETWORKS OF COMPUTER AIDED DESIGN REPOSITORIES and CO-WORD GRAPHS […]

Poster accepted: Design Computing and Cognition

Harry has had a poster accepted to DCC 2020 in Atlanta, Georgia for the end of June. The work presented looks at the capability of varying mass properties in rapid protoyped parts by manipulating the infill density through the part(s). This work follows on from Harry’s work on identifying the effect on user perceptions of […]

Mass property mapping: first paper accepted – Design 2020

Harry’s first paper has been accepted to Design 2020! Titled “Looks like but does it feel like? Investigating the influence of mass properties on user perceptions of rapid prototypes” the paper looks at how mass, balance and inertia are considered by people through manipulation of an example part. It was found that each of the […]

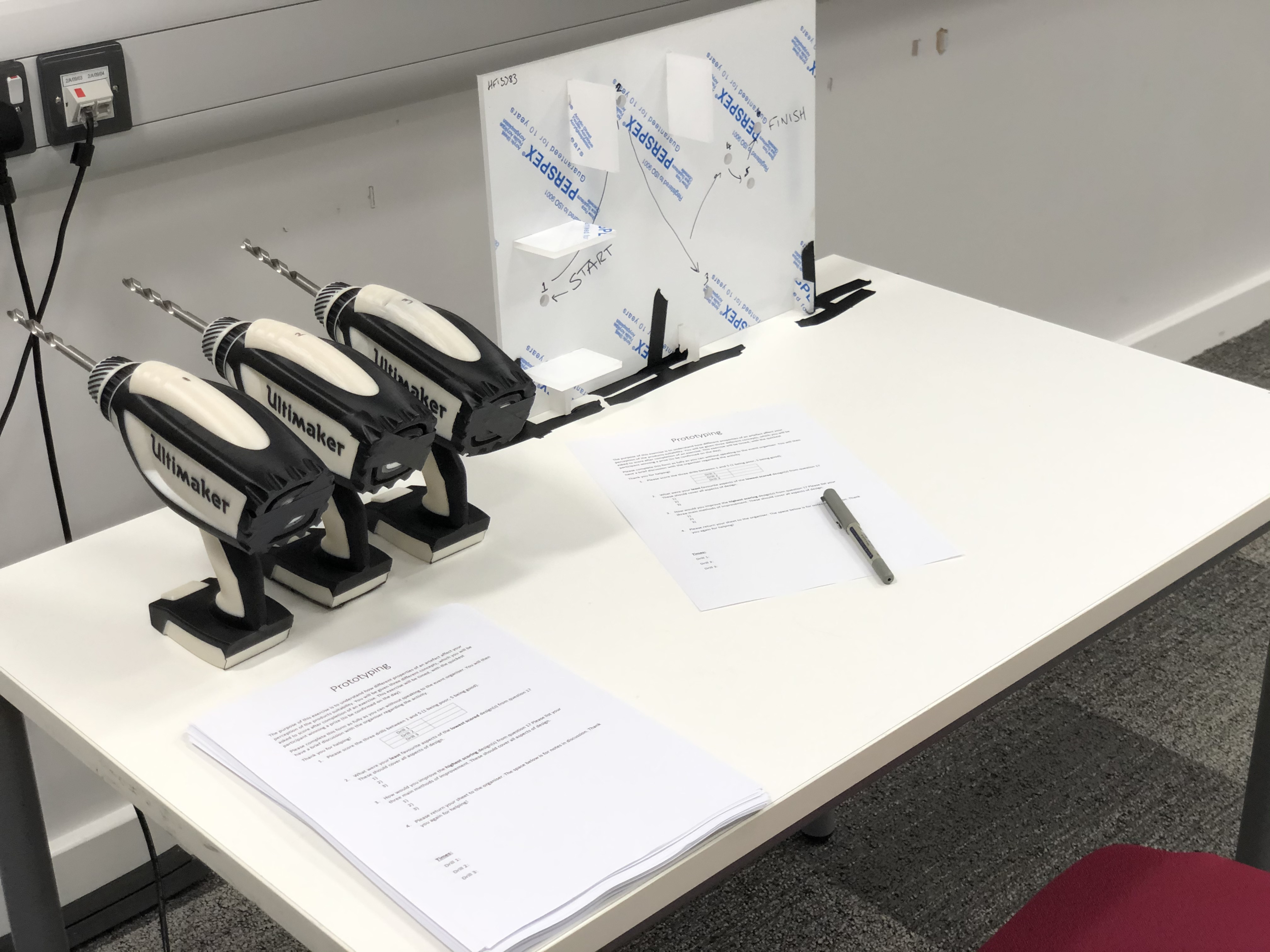

Looks like but does it feel like?

Harry has been completing early investigatory studies as part of his PhD work. This has focussed on the completion of a study, completed within the Department of Mechnical Engineering, that focused on how mass properties (mass, balance and inertia) affect a user’s perception of a product. The study used a drill model printed on an […]