The 14-18 November saw the Design & Manufacturing Futures lab descend attend FormNext 2022 in Frankfurt. The team had a stall to showcasing the world-leading research it has been doing in the areas of Machines with Minds and the Future of Prototyping. We also gave two presentations setting out visions for the future of AM supply chains and electrical machine design. It was great to get out and see the status of the AM industry and to get industry feedback on our research.

The show was across 4 massive halls and it was great to see the diversity in offerings with businesses of all sizes and specialities being able to contribute to the AM ecosystem. The feedback was incredibly positive and we look forward to following up with the networks we formed over the next few months.

Machines with Minds

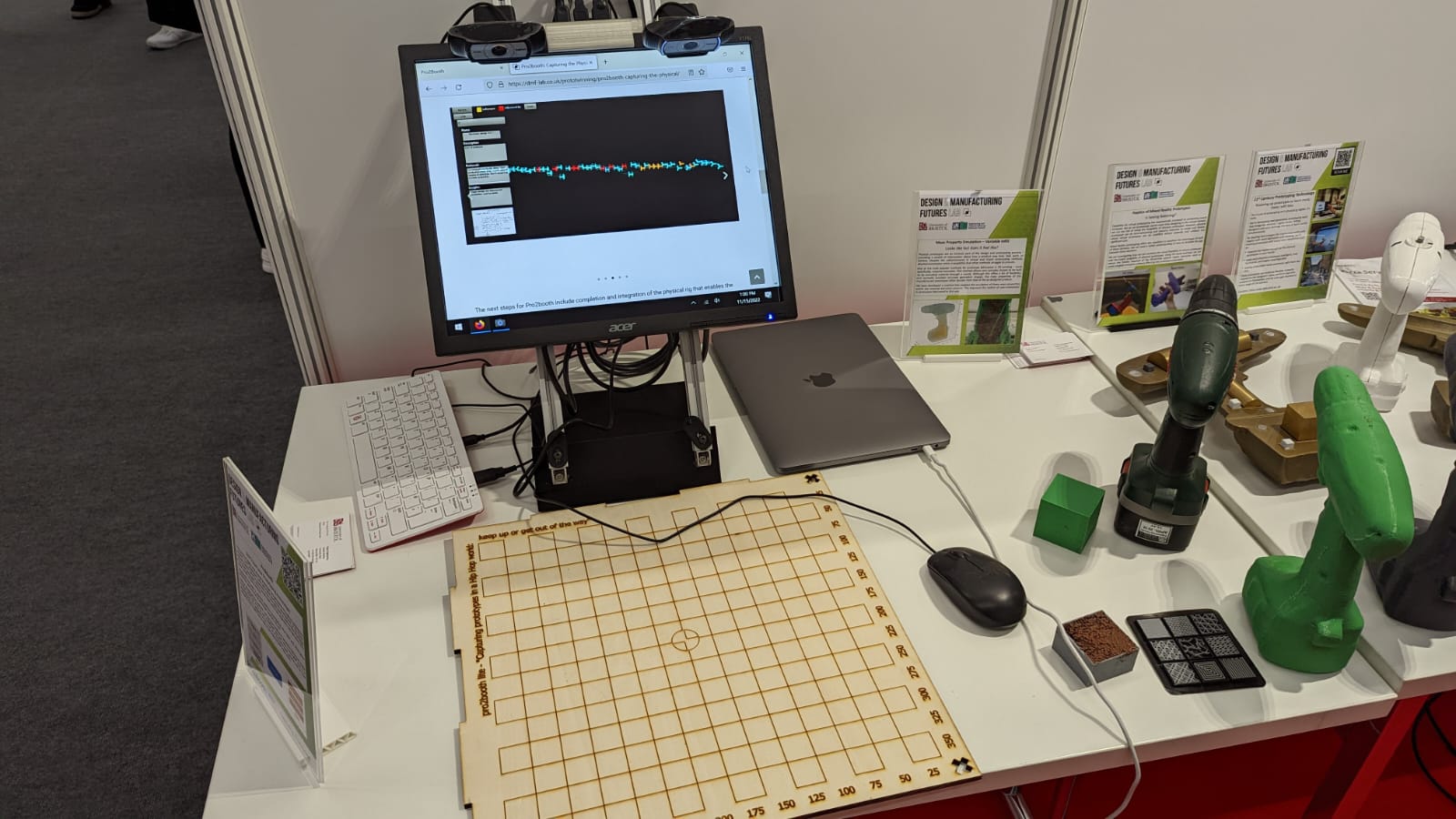

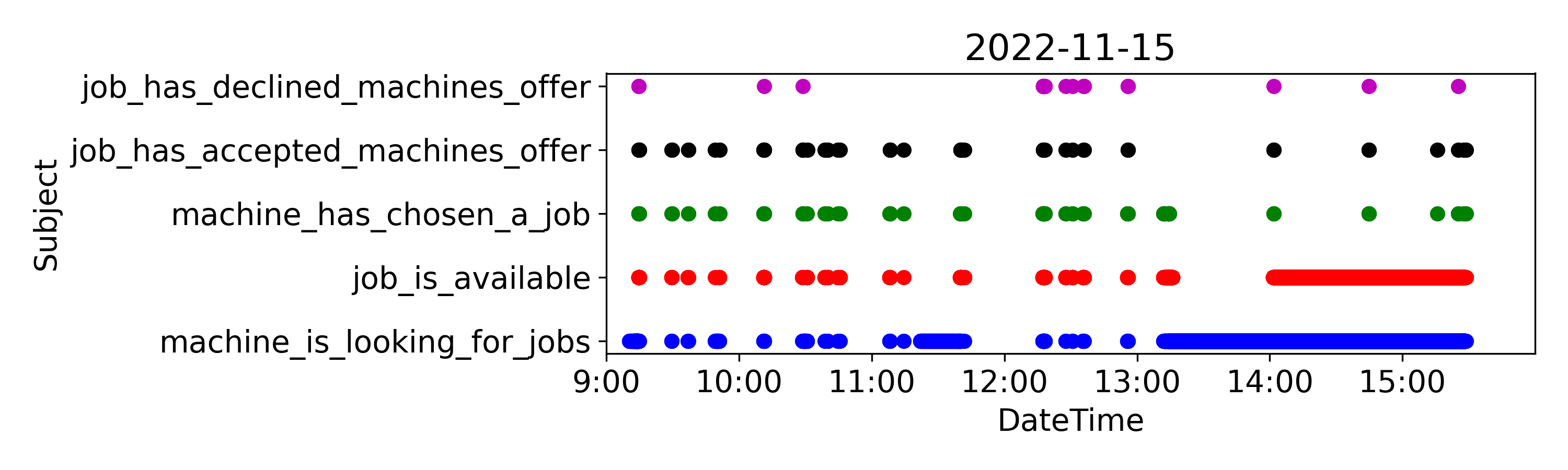

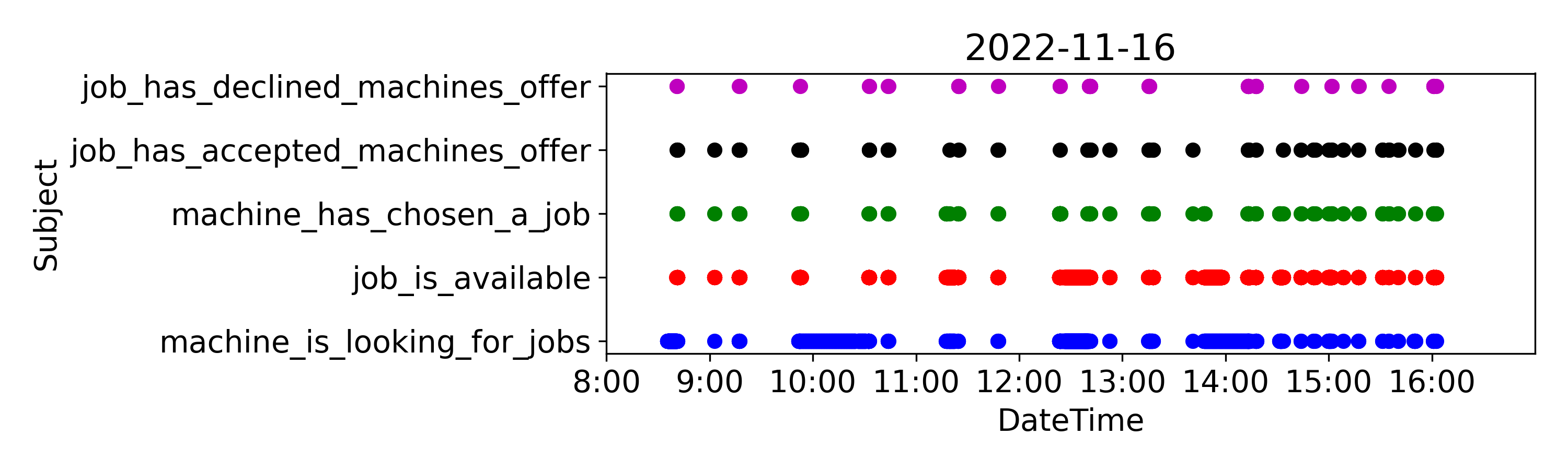

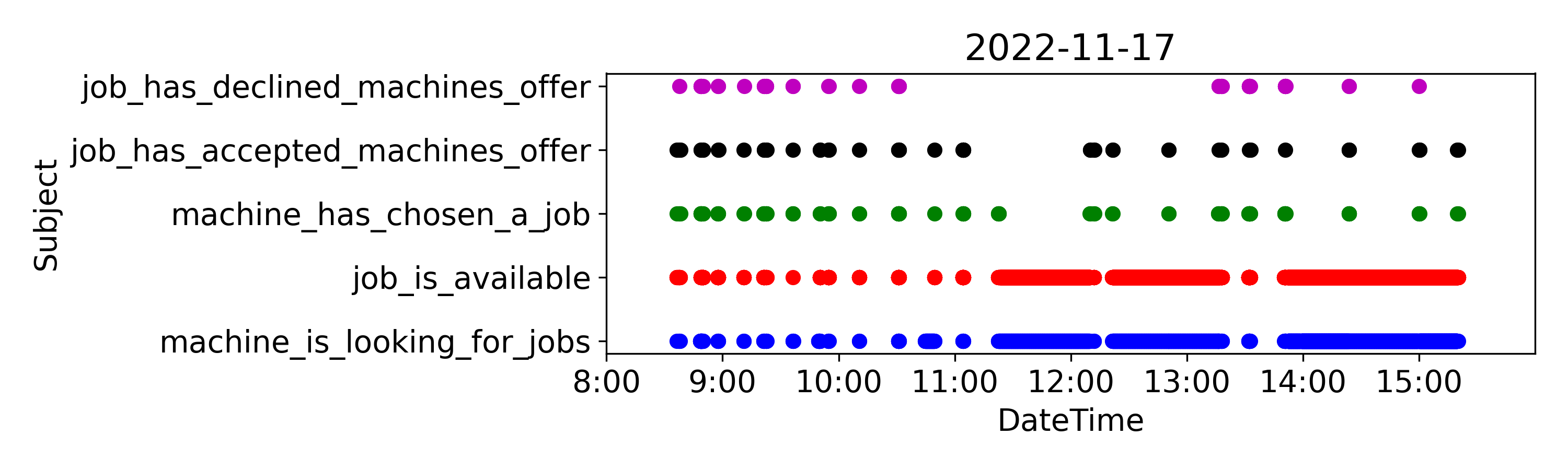

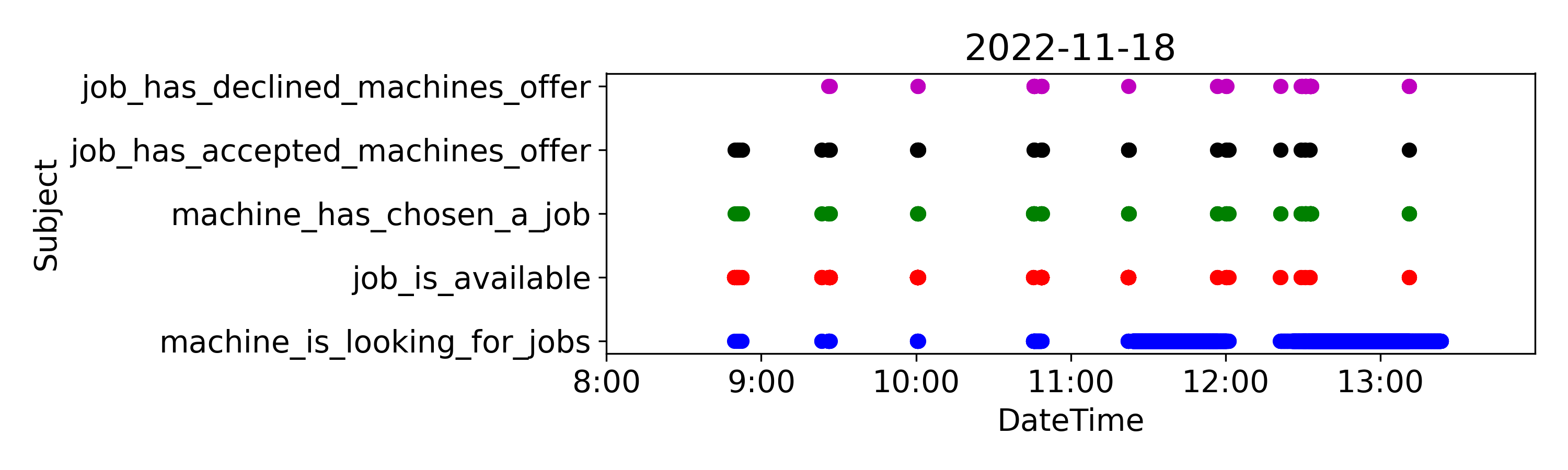

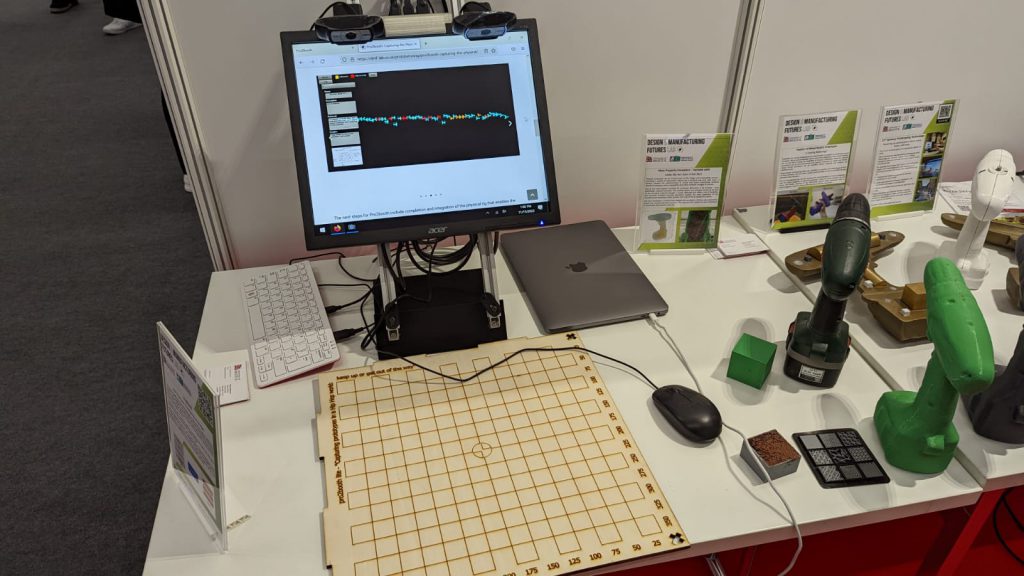

The team installed four AM machines capable of talking with one another and bidding for jobs that joined our FormNext Brokering Additive Manufacturing (BAM) network. Over the course of the event, the machines bidded for and completed 222 jobs! Below are some figures showing the communications that occurred across the network. You can see that some jobs declined the offers from machines showing there was some squabbling going on. 😀. We look forward to examining this further as part of validating our theories about the service.

The industry feedback was very positive and many were excited at the prospect of their machines autonoously managing their workflows. Of note, they:

- were surprised and excited to see that it could be achieved using today’s technologies.

- liked the lack of a central server storing IP (design data) and that design data is only transmitted once a deal has been brokered.

- liked the extensible nature of the network with machines being able to join and exit at a moments notice.

- liked that it is machine agnostic with the capability to join a diverse set of machines together and for them to have different goals to one another.

We look forward to following up with a number of interested parties who wish to trial the approach.

The Future of Prototyping

The team presented Pro2Booth, a framework for capturing and digitising prototying insights and knowledge. Thois has been instantiated within a web service where wone can visualise a design project by its prototypes and what was learnt from them. We had some great feedback on how industry currently captures this knowledge and that a system, such as Pro2Booth, would fill a missing link the managing the data, information and knowledge during product design.

The researchers als showcased research into how Additive Manufacturing and Augmented/Virtual Reality can be used to manipulate the fidelity of a prototype. Through the use of varying infill and automated slicing and positioning of standard masses, we are able to capture the ‘feel’ of a product much earlier in the design process through the relpication of a product’s predicted mass properties. The team went further to show how a realitvely simple physical model can be coupled with a high-fidelity model to give stakeholders the ‘feel’ of the real thing. This enables stakeholders to provide much more detailed feedback on a design much earlier in the design process.

Jennifer talks about the future of AM supply chains

Dr Jennifer Johns spoke about the future of supply chains and that work being done at the University of Bristol ad the Brokering Additive Manufacturing project to realise de-centralised and distributed manufacturing.

Nick talks about the future of electrical machine design

UKRI Future Leaders Fellow Dr Nick Simpson presened work showing how Additive Manufacturing (AM) offers the design freedom required to provide transformational gains in electric machine performance.

Highlights from the team

Here are some highlights from the team:

Harry Felton

It was great to be back at in-person conferences after 2 years of moving online, and a great first visit to FormNext for the team. There was lots of interest in the projects spanning the Design and Manufacturing Futures Lab and The Electrical Machine Works, which is always good to see!

For me, the increase in quantity and quality of copper being printed was very encouraging. This will help lead to greater advances in the applications of additive manufacturing within electrical machines! It was also very interesting to see the investment in automating factories and starting to close the loop on additive systems.

Mark Goudswaard

Similar to my colleagues it was great to be back at these kind of events in person and to be able to meet a range of people working in the field. FormNext as a trade show is a great place to get a feel of the AM industry internationally with a staggering amount of companies working in this space. Working in academia one can become isolated in one’s projects and field without being aware of the wider work going on in industry. Attending and exhibiting at FormNext was a great opportunity to understand how one’s individual research fits into the global whole.

A highlight for me was seeing the new optimisation software (eiger.io) from MarkForged that looked to optimise manufacturing parameters for particular load cases with FEA but underpinned by lots of material testing data – something not entirely different to my PhD work… great minds!

Chris Cox

It was a great experience to get a deep insight into the world of AM – and a brilliant opportunity to discuss our projects with industry. It’s very easy in academia to lose track of what the state of play is in the industrial world, and events like FormNext help us to keep our finger on the pulse!

The best moments for me were discussing my research direction with representatives from different industrial sectors, to get some insight into how it might be applied in ways I hadn’t thought of.

Lorenzo Giunta

FormNext has been a wonderful opportunity to see some of the state of the art in AM and to interact with leading players in the field. We have been able to connect and discuss what the research that the University of Bristol is conducting could mean for them as well as get better insights into where they believe the future of AM may lie. It was particularly interesting to see not just some of the newest machinery available on the market, but also hear of the long term goals held by many companies both big and small. This is invaluable information for us to aid our research grow symbiotically with the needs of industry, thereby helping bridge the gap between the technology push that the University of Bristol is so well known for and the market pull that can be sometimes difficult to accurately pin down.

Summary

Formnext was a fantastic experience enabling us to review the AM industry state-of-the-art. It was great to see the excitement and interest in our research and we look forward to following up with people we met and creating the innovation pipelines that can bring our research to industry.

Please get in contact us about anything you have seen. There are lots of opportunities to work with us through student projects, joint PhDs, innovation and research grants, sponsoring our opensource codebases, advisory committees, contracted work and consultancy work.