As part of project clean access, we wanted to establish what the response of the maker community had been to the covid pandemic. To do this, we created a catalogue of covid innovations that were published during the pandemic.

We then ranked each innovation based on metrics such as Technology Readiness Level (TRL), usefulness, practicality and inclusivity, which were self defined, with the aim of selecting products to redesign and improve.

The first product selected for redesign was an open source polymerase chain reaction (PCR) machine, which is used to amplify and analyze small samples of genetic material.

While PCR machines are widely available, they are expensive and may not be accessible to everyone. One example of an open source PCR machine is the OpenPCR project. The OpenPCR machine is based on the Arduino open source platform, which makes it easy to modify and improve upon.

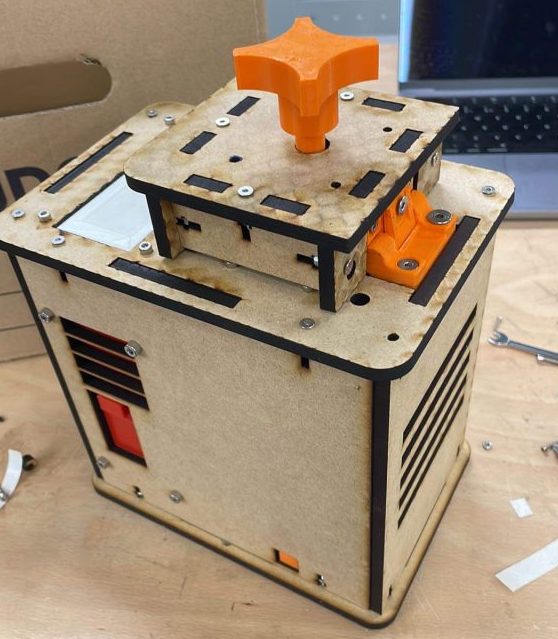

We began the redesign process by manufacturing the original design from OpenPCR. 3D printed representations were used in place of the mechanical parts as our redesign was focused on part reduction and improving the ease of assembly.

The original housing was fastened using a common slot method for holding bolts in place. We found this fiddly while assembly and was the source of a great deal of frustration. It also necessitated a high part count, with 16 nuts and bolts required to assemble the main body alone. The small M3 nuts and bolts required a great deal of dexterity to slide into place, making the product difficult to assemble for those with larger hands, or those with motor difficulties.

With the aim of reducing part count and increasing ease of assembly, we converged on the idea of living hinges, to allow the box parts to be printed as one piece, with slots to allow assembly without fasteners.

A living hinge is a series of laser cut slots which, due to the small gaps between each, allow the material to bend in a very natural way. The use of these living hinges allowed for the elimination of all fastenings from the main housing. This equated to a part count reduction for the housing of 92%!

Once the living hinge approach was shown to be effective, the geometry for mounting the hardware was translated to the new design. Design for assembly principles, such as asymmetrical slots, were implemented to ensure that the housing could only be assembled in one way.

While the original design was certainly functional, it was clear that little attention had been paid to the assembly process, with thought, and solid DFA principles applied, the product could be improved significantly.

Also of note is a phenomenon not unique to this product, but seen repeatedly throughout the innovation cataloguing process, was that of the ‘open source’ design. While technically open source, this PCR machine requires a bespoke PCB to be fabricated, as well as several machined aluminium parts. This makes the barrier to entry for building this very high, and likely out of reach for the average hobbyist. While it does make use of off the shelf components, the necessity of a bespoke PCB is limiting.

Overall the redesign was considered a success, with a significant reduction in part count and the assembly experience improved through reduction in the frustration experienced as a result of fiddly fixings. It can also serve as a demonstration that many of the covid innovations published, while functional, could benefit from a user focused redesign.

The DXF files and other information associated to this project can be found in the DMF lab Github repository for project clean access.