I’ve started work on my first sprint looking at coupling additive and subtractive manufacturing (termed hybrid manufacturing) for use within digital twinning.

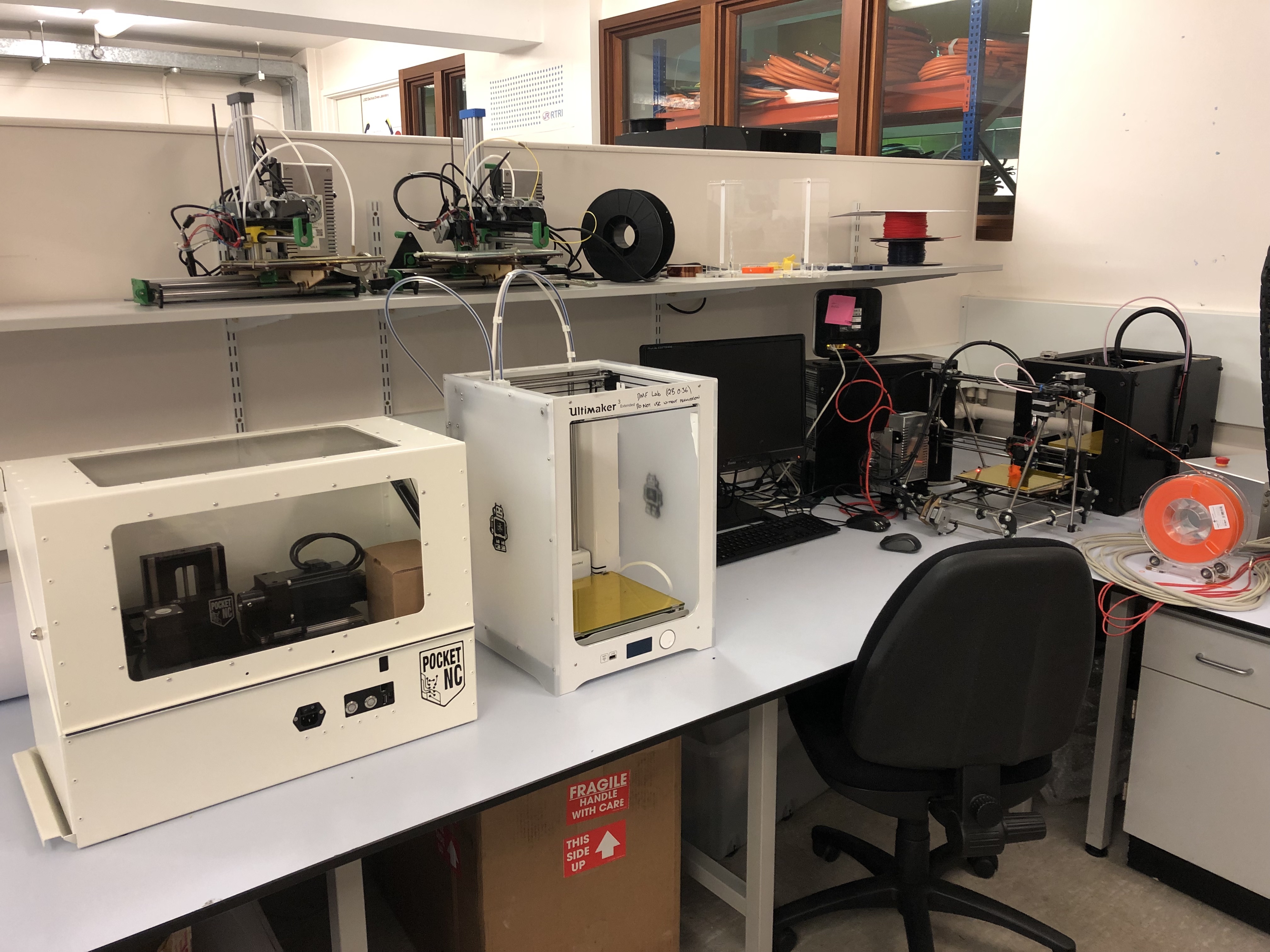

Using the research group’s new lab space – the digital manufacturing lab at the University of Bristol – I’m going to be investigating the machining of FDM produced parts with the aim of creating a set of guidelines. These guideline will be used to further the use of hybrid manufacturing with digital twinning in early design stages.

Hybrid manufacturing has the unique capability of mitigating the negatives and taking advantage of the positives of both the additive and subtractive processes. Through doing this, the digital-to-physical domain transition can be sped up, made to be more accurate and produce parts with better surface finishes. All of these are advantageous in the early design stages.

I’ll make sure to keep this updated with the latest updates and new projects!